A Brief Primer on FedEx’s Distribution Network

With a map!

*Updated July 1, 2025

FedEx was founded in 1971 as an express delivery service. An early motto captures its basic promise: “When it absolutely, positively has to be there overnight.”

The Federal Aviation Act of 1977, which was intensely advocated for by FedEx founding president Fred Smith, allowed FedEx to bring larger aircraft into its fleet. Larger aircraft in turn allowed FedEx to concentrate most of its sorting operations in one hub, Memphis, where the company built its superhub in 1979. Today Memphis is the largest cargo airport in the country, and second in the world, all thanks to FedEx’s massive operation.

While FedEx was founded as an air service, and UPS as a ground service, both FedEx and UPS have air and ground services today, though FedEx still has an edge in the air game, with 741 aircraft it operates as opposed to UPS’s 506. It is the largest cargo airline in the world, serving more than 650 airports around the world and shipping 16 million packages daily.

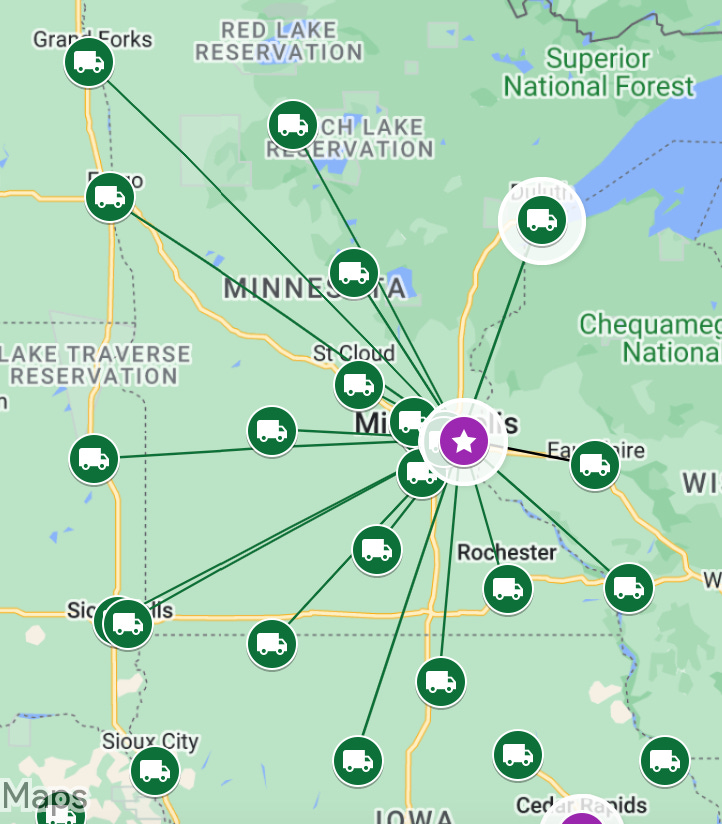

As with all of our primers, this one has an associated map of FedEx’s Distribution Network, which On the Seams will do its best to keep updated. (Once again, if you have an update to this map, email us at ontheseams.newsletter@gmail.com.)

Express

FedEx traditionally generates between 55-60% of its revenue from Express, about 25% from Ground, 10% from freight, and the remainder from other services.

Speed is the name of the game for Express, so everything in this operation is about getting packages on and off planes as quickly as possible. At many airports (102 by my count), they have Air Freight Centers (AFCs); these are also listed publicly. Employment levels at these AFCs range widely, from 27 in Grand Junction, CO to 643 at JFK. They also have a whole bunch of Ship Centers that are either on airport grounds or just a few blocks away, and I’ve listed these on the map as well. (Note, only the Ship Centers close to airports are on the map. FedEx has many other Ship Centers, the spoke nodes of the Express system, and you can search for them on FedEx’s site.)

Express operates by a hub-and-spoke logic, which the company pioneered, though the spokes typically have their own mini-spokes as well. For instance, a package coming from Grand Forks, North Dakota will first go to Fargo, North Dakota (KFAR), be processed at its Air Freight Center there, and then go on to FedEx’s world hub in Memphis (KMEM), where it’s sorted to its destination.

By far the largest Express sort facilities are in Memphis and Indianapolis (KIND), the latter being FedEx’s national hub. KIND has about 180 flights in and out every day, KMEM about 250. Around 5500 people are employed at the facilities around KIND, and more than 20,000 at the facilities around KMEM. Both facilities can handle more than 2 million packages a day; a package can be in and out of a sort facility like this within 15 minutes. In addition to these superhubs, there are smaller regional hubs in Anchorage (PANC), Fort Worth (KAFW), Greensboro (KGSO), Miami (KMIA), Newark (KEWR), Oakland (KOAK), and Ontario (KONT).

Sortation is a science all its own, and we will devote a separate primer to various sort logics, operations, technologies, etc. But the basic goal of these sort hubs is all the same: get inbound packages organized on conveyor belts so that they can be scanned and kicked to slides/chutes with other packages bound for the same area.

FedEx Express pickup and delivery drivers are employees of the company. Unlike with Ground, which will send a driver out for the day to do pickups/deliveries, Express drivers typically have to work around time-committed packages, meeting one or a few loop deadlines for the day, doing on-call pickups, and making a certain number of required delivery attempts.

Ground

FedEx Ground was founded in 1985 as Roadway Package System (RPS). It was bought in 1998 by FedEx and rebranded as Ground in 2000.

Like Express, Ground operates by a hub-and-spoke structure. Let’s say a package is dropped off at a FedEx store in Cloquet, Minnesota, and it’s going to Chandler, Arizona by Ground. It will first get picked up and sent to the local Ground Facility in Superior, Wisconsin (ZDUL), and then sent to the regional Ground Hub in St. Paul (STPL). The Ground Facilities are in green, and the Ground Hubs are in purple. Below is depicted the spoke structure around the St. Paul hub; highlighted are the hub itself and the Superior facility.

From STPL, the package goes on a linehaul run to another Ground Hub, in this case the one in Phoenix (PHOE). The hub structure allows FedEx to consolidate shipments for long-distance travel, but in this case in full truckloads rather than on full planes. Then from the PHOE hub it goes to the Chandler Ground Facility (ZCHD), and then out on a delivery truck.

Once again, you have the hub-and-spoke structure around the Phoenix hub, but in this case the package goes out toward a spoke facility rather than into a hub from it.

Also represented here in brown are the Regional Sort Facilities, which can process 12-15,000 packages/hour and are something like inbound facilities for large retailers—entry points that are typically situated close to Ground Hubs. They can also help with sortation during peak season, and so also serve as spillover sortation centers.

Each Ground Hub employs 1,200 people on average. Employment at Ground facilities varies widely, but there are about 200 employees working at each on average. Average employment at a Regional Sort Facility is 575. This is all according to 2024 OSHA ITA data.

Unlike with Express, where drivers are employees of FedEx, Ground P&D drivers work for third-party Independent Service Providers (ISPs), which contract with FedEx to pickup/deliver packages in a specific geographic area. ISP contractors, of which there are roughly 5900 in the US, are required to cover at least 5 routes or 500 daily deliveries. The linehaul drivers are also independent contractors but work for what FedEx calls Transportation Service Providers (TSPs). Both ISPs and TSPs are considered CSPs (Contracted Service Providers).

Freight

FedEx Freight is its less-than truckload (LTL) business; it handles shipments weighing over 150 lbs. It operates about 30,000 vehicles out of roughly 400 Service Centers, which are included on the map. It also appears to operate by a hub-and-spoke system, though I have not been able to determine the hubs thus far (and will update this primer if I can).

Freight has a much higher operating margin than Express or Ground (20-22% as opposed to 8-9% and 11-12% respectively), and the company is in the process of spinning it off into its own company in order to “unlock sustainable shareholder value.” At the same time that it is organizationally separating Freight into its own unit, however, it’s also integrating the Ground and Freight networks as part of their much anticipated Network 2.0 initiative. A large number of Freight Service Centers have been closed in the past two years.

Supply Chain

FedEx also has a relatively small Supply Chain segment that provides different logistical services, including warehousing, order fulfillment, freight forwarding, transportation management, and other specialized services. It claims to have 30+ fulfillment centers, 130+ distribution centers, and more than 40 million square feet of warehouse space.

Again, Supply Chain is a negligible part of FedEx’s overall operation, but they do have some pretty big facilities in that segment. For instance, they operate a distribution center for Target in York, PA and one for T-Mobile in Coppell, TX that each employ about 1,200 people.

Network 2.0

In 2022, FedEx announced its intention to create Network 2.0, which will unsilo its previously independent operations. As Satish Jindel explains here, both FedEx and UPS’s Ground operations have become so fast that they’ve unintentionally created competitors for their Express services. The average time that a package spends in the FedEx Ground system is a mere 1.9 days. FedEx is telling its contractors that it is merely piloting network integration at present, but that they should begin to see significant overhaul to the network in 2026 and 2027. FedEx is planning to shrink its distribution network from roughly 1200 facilities to about 1000.

In more remote locations, like Yakima, Kennewick, and Lewiston (pictured below), FedEx will often have flights going in and out of the regional airport and also have a Ground Facility and Freight Service Center. An integrated network will likely not see this same kind of redundant clustering.